Engineered quartz

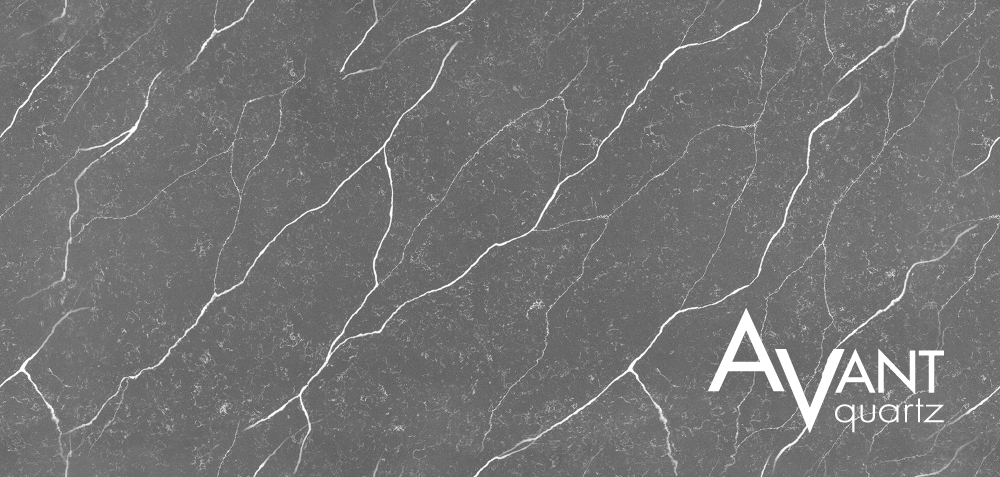

Engineered quartz is a hi-tech composite material made from natural quartz and polyester resin. It has a similar appearance and texture to natural stone, but with added benefits such as being non-porous and highly durable. Engineered quartz is resistant to scratches and shocks, and does not absorb liquids or promote mold growth. It is easy to clean and maintain, making it a popular choice for both indoor and outdoor use. With a wide range of colors and patterns available from top brands, the possibilities for design are endless. Please take a look at the newest colors from these famous engineered quartz brands:

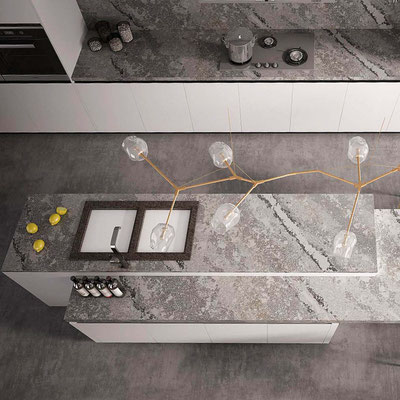

Engineered quartz can be used to create a variety of surfaces, from worktops, tables to windowsills. Whether you're looking to add a touch of elegance to your living room room or create a sleek and modern reception area, quartz is a great choice. Its large slab size means that there are fewer joints, making it a great choice for cladding walls and floors. Quartz sheets work well when creating large furniture pieces in public spaces like reception areas, restaurants, and bars. With its sleek and modern look, engineered quartz will add a touch of freshness and style to any space.

engineered quartz fabricators in Lithuania

Advantages of engineered quartz

Engineered quartz is a popular choice for countertops and other surfaces due to its practicality and beauty. Despite its luxurious appearance, it is quite easy to maintain. Unlike natural stone, quartz is non-porous, making it resistant to stains. Simply clean the surface with soap and water, and don't to worry about liquids seeping into it. This means you can enjoy your quartz countertops without the need for sealers or waxes, making it a hassle-free option for any home.

Engineered quartz is just as durable as granite but is less rigid due to added resins that make it slightly flexible. It is highly resistant to scratches and other external impacts. Unlike natural stones, engineered quartz has a uniform internal structure, which means it does not contain hidden cracks or impurities. This also means that quartz slabs of the same type have a consistent color and pattern. Overall, engineered quartz is a great choice for those looking for a durable and consistent material for their countertops or other surfaces.

Another major advantage of engineered quartz is its safety. Unlike some other materials, it does not release harmful chemicals or radiation into the air, making it non-toxic and non-allergenic. Most engineered quartz products are certified by the Green Guard Environmental Institute, which guarantees that they release the lowest possible levels of volatile substances into the environment. Engineered quartz a great choice for those who prioritize safety and sustainability in their home design.

One of the advantages of using engineered quartz for your countertops is its ability to withstand moderate heat (up to 150°C). While it may not be as heat-resistant as granite, marble, or sandstone, it can still handle accidental exposure to hot pots and pans. However, it's important to note that prolonged exposure to lower levels of heat can still cause damage. To prevent any discoloration or damage, it's recommended to use trivets when placing hot items on your quartz surface. In the rare event that an open flame or extremely hot object comes into contact with the surface, it's possible for the resins in the material to cause discoloration.

With a vast array of stone-like patterns available, it can complement any kitchen style, from modern to traditional. However, it's important to note that glossy black surfaces may show fingerprints more easily. Fitting the sink underneath the countertop creates a seamless and tidy appearance, making cleaning very simple. Say goodbye to scraping and brushing and hello to a sleek and functional kitchen surface.

Engineered quartz has become a popular choice for not only kitchen countertops, but also for other surfaces throughout the home. With its durability and versatility, quartz can be used for windowsills, coffee tables, walls, and even flooring. The large size of quartz slabs also means that there are fewer joints, making it a great option for spacious areas like reception areas, restaurants, and bars. Plus, the sleek and modern look of quartz adds a touch of elegance to any space.

It is important to note that although polyester resin binders give to quartz slabs some flexibility which prevents their cracking (due to bending or pressure), these binders gradually harden. This results in a quartz slab losing its flexibility over time. Polyester resins can be affected by ultraviolet rays, therefore artificial quartz should rather not be used outdoors. Continuous exposure to UV light can also cause discoloration and disintegration of the resin binder.

Engineered quartz suppliers

How engineered quartz is made

The process of making engineered quartz involves a mixture of ground quartz (95-97%), polyester resins (3-5%), and pigments. The percentage is counted by weight. This mixture is compressed using a vibrating compressor and any air is removed. The resulting mass is poured onto a moving belt, shaped, heated, and vacuum-compressed at high pressure. Finishing absorbents are added to prevent color changes caused by UV rays.

After 24-48 hours, the cured panels are polished. Some companies import their own stone chips, while others purchase already crushed stone powder. Engineered quartz made with unsaturated polyester resins boasts low water absorption, excellent chemical durability, remarkable hardness, and resistance to bending and temperature changes, making it superior to granite or marble.

What are engineered quartz properties?

- Long life

- Hygienic

- Non-porous

- Seams are visible

- Non-toxic

- Hard

- Durable

- Resistant to stains

- Resistant to flame

- Resistant to heat up to 80ºC

- Resistant to wear

- Resistant to UV rays

- Easy cleaning and maintaining

- No sealing required

What is engineered quartz used for?

Kitchen worktops

Bathroom vanities

Wall cladding

Window sills

Swimming pools

SPA and wet rooms

Stairs

Floors

engineered quartz examples in home interior

How to clean engineered quartz worktops

Cleaning engineered quartz worktops is a breeze. Simply use warm water and dishwashing liquid to wash them regularly. Because this material is non-porous, liquids, mould, and bacteria cannot penetrate it. Engineered quartz does not require regular sealing. Avoid using abrasive brushes as they can scratch the surface. Certain cleaners and chemicals can damage or discolor quartz surfaces. To keep your worktops looking their best, avoid contact with drain cleaners, oven cleaners, paint strippers, solvents, acetone, nail polish removers, and acidic cleaners.