quartzite

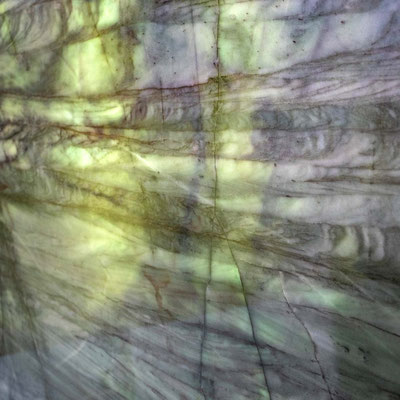

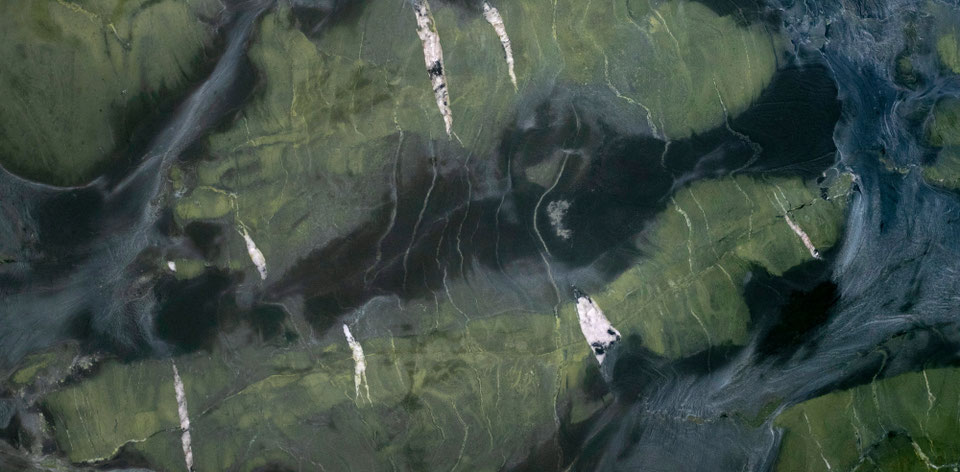

Quartzite is a very hard rock whose excellent qualities often surpass those of granite. Pure quartzite is white, but due to impurities trapped in this natural stone it can surprise with fabulous colors and amazing patterns. Quartzites can be pink, green, blue, purple. Some of them look transparent, some look milky or veiny, others remind of shattered ice or dry, fractioned earth. Translucent quartzite slabs resemble thick glass chunks with inclusions. The beauty of quartzite is hard to resist.

With a Mohs hardness of 7-7.5, quartzite in architecture is superior to both marble and granite. However, quartzite is much more expensive. Funny enough, sometimes quartzite can disguise as marble or granite by mimicking their appearance. Quartzite is highly resistant to atmosphere's chemical and physical effects, such as changes in temperature, humidity, air pollution. It is one of the most physically durable and chemically resistant rocks found on the Earth.

quartzite fabricators in Lithuania

What makes quartzite unique?

Quartzite is highly valued for its beauty, durability, and unique properties. Here are a few characteristics that make quartzite stand out from other stones used in architectural and decoration projects:

- Composition: Quartzite is a metamorphic rock that is formed from sandstone through intense heat and pressure. It is composed of quartz grains that have been fused together by heat and pressure, which gives it a unique and beautiful appearance.

- Durability: Quartzite is one of the hardest natural stones available, making it highly resistant to scratches, chips, and other types of damage. Because quartzite is more scratch-resistant than other stones, it is perfect for making stairs, laying floors in high traffic areas. Being more resistant to many chemical substances and acids, quartzite is an ideal choice for kitchen countertops.

- Appearance: Quartzite has a unique and beautiful appearance that can range from light grey to pink, red, and even green. It often has striking patterns and veining that can be subtle or bold.

- Versatility: Quartzite is a versatile stone that can be used in a variety of applications, including flooring, countertops, walls and partitions. It can be polished to a high shine or left with a natural, textured finish.

- Maintenance: While quartzite is highly durable, it does require special maintenance to keep it looking good. However, it should be sealed regularly to protect against stains and spills. Spilled acidic substances should be cleaned up immediately to prevent etching.

Overall, quartzite unique properties make it an excellent choice for a wide range of applications, from kitchen countertops to flooring and beyond. Quartzite is superior to marble and granite in architecture because of its resistance to atmosphere's chemical and physical effects. Quartzite is not affected by changes in temperature, humidity or pollution. Where natural forces erode mountains and weather less resistant rocks, quartzite ridges remain.

Engineered quartz resembles quartzite in many ways. It can match quartzite in durability and performance. Regarding price, engineered quartz worktop will result less expensive than natural quartzite. Another artificial stone type whose properties resemble those of quartzite is sintered stone. To install a sintered stone worktop is more expensive than engineered quartz. The price of the final sintered stone item can be similar to that of natural quartzite.

Pure quartzite is usually white to grey, though quartzites often occur in various shades of pink and red due to varying amounts of iron oxide (Fe2O3). Other colors, such as yellow, green, blue and orange, are due to other minerals.

How quartzite is formed

Quartzite is a naturally occurring metamorphic rock. It is formed from sandstone under intense heat and pressure deep in the Earth's crust. Extreme heat and pressure usually occur because of tectonic compression. Given these conditions, the grains of sandstone fuse together to form a new rock that is extremely hard. When transforming into quartzite, sandstone totally changes its color and appearance. This transformation is called metamorphosis, and the resulting rock type is called metamorphic.

As the sandstone transforms into quartzite, the quartz particles re-crystallize with impurities to create amazing crystal mosaics. Almost all the particles that make up sandstone fuse together, and the former rough surface of the new rock becomes glassy and smooth. Minor amounts of former cementing materials, iron oxide, silica, carbonate and clay, often migrate during recrystallization and metamorphosis. These impurities decorate the newly born quartzite with veins, circles and other patterns. This also causes streaks and lenses to form within the quartzite. Inherently white or grey, quartzite becomes mottled, yellowish, green, blue or orange. Brownish and pink quartzite is also found.

Where quartzite is found

Quartzite is typically quarried in large blocks from mountainous areas around the world, including Brazil, India, Norway, and the United States. Some of the largest quartzite quarries are located in Brazil and India. It is also found in Canada, UK, Germany and the Czech Republic. In Ireland, areas of quartzite occur in the west and north-west, with the most prominent outcrop being Errigal Donegal. Norway has one of the largest quartzite quarries in the world. The Mozambique's highest mountain Monte Binga (2436 m) and the surrounding plateau are composed of very hard, light grey Precambrian quartzite.

How quartzite is quarried

The process of quarrying quartzite involves several steps:

- Prospecting: The first step in quarrying quartzite is to locate a suitable deposit. This is usually done by geologists who study the area and identify potential sites.

- Clearing the land: Once a suitable deposit has been identified, the land around the deposit is cleared to provide access to the rock.

- Drilling: After the land is cleared, long rows of parallel drill holes are made in the rock using specialized equipment. These holes are used to place explosives.

- Blasting: Explosives are placed in the drill holes and detonated to break up the rock. It is important to assure that the explosion is strong enough to separate the block from its bed, but gentle enough not to crush it.

- Extraction: The broken rock is then extracted from the quarry using heavy machinery such as excavators and front-end loaders. These rough quartzite blocks are transported from the quarry to warehouses by heavy machines.

- Cutting and shaping: The extracted rock is cut into blocks of various sizes using saws and other cutting equipment. The blocks are then shaped into specific dimensions using specialized tools: most often they are nicely cut into 2-4 cm thick slabs.

- Finishing: the quartzite blocks are finished by sanding and polishing to give them a smooth and shiny surface.

- Transporting: Finally, the slabs are transported to stone fabricators' workshops. The stone professionals cut the slabs by diamond saws to custom orders and polish them by stone polishing machines. This is how quartzite worktops, window sills, floors and stairs appear in your home.

quartzite properties

- Very hard (hardness according to Mohs scale – 7-7.5)

- Resistant to etching

- Resistant to chemical weathering

- Harder than granite

- More resistant to stains than granite, but less resistant than engineered quartz

What is quartzite used for?

Kitchen worktops

Bathroom vanities

Furniture tops

Wall cladding

Flooring

Stairs

Fireplace surrounds

Window sills

How to clean quartzite worktops?

Quartzite worktops are a popular choice for kitchens and bathrooms due to their durability, beauty, and resistance to heat and scratches. However, like any other surface, they can become dirty over time and require regular cleaning to maintain their good appearance. Here are some steps to clean quartzite worktops:

- Wipe the worktops with a soft cloth or paper towel to remove any loose dirt or debris.

- Mix a solution of warm water and mild dish soap in a bucket or spray bottle. Avoid using abrasive cleaners, as they can damage the surface of the quartzite.

- Dip a soft cloth or sponge into the cleaning solution and wring out any excess water. Gently wipe the surface of the quartzite, paying special attention to any areas with stains or spills.

- Rinse the cloth or sponge with clean water and wipe the surface again to remove any soap residue.

- Dry the quartzite with a clean, dry cloth to prevent water spots or streaks.

- For tougher stains, you can use a paste made of baking soda and water. Apply the paste to the stain and let it sit for a few minutes before wiping it away with a damp cloth. Rinse the surface with clean water and dry with a clean, dry cloth.

It's important to note that while quartzite is a durable and hard-wearing material, it is not completely stain-proof. To minimize the risk of staining, it's important to clean up spills and stains as soon as possible. Like any other natural stone surfaces, quartzite worktops need to be sealed. Avoid placing hot pots or pans directly on the surface of the quartzite to prevent damage to the finish.